Robert F. Bourque, Ph. D., P.E.

Bourque Engineering LLC

Los Alamos, New Mexico USA

bob@rfbourque.net

505-412-0194

Chapter |

Title |

1 |

|

2 |

|

3 |

|

4 |

|

5 |

|

6 |

|

7 |

|

8 |

|

9 |

|

10 |

|

11 |

|

12 |

|

13 |

|

14 |

|

15 |

|

16 |

|

17 |

|

18 |

|

19 |

|

20 |

|

21 |

|

|

|

|

|

|

A Compact Pollution-Free

External Combustion Engine

with High Part-Load Efficiency

Previous Chapter | Next Chapter

16. Materials

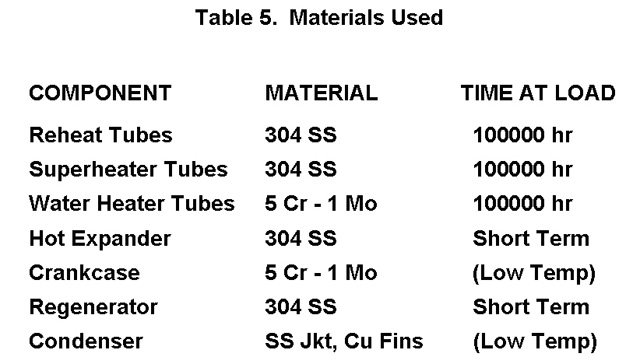

These engines are intended to be mass-produced. Therefore materials used must be readily available, not difficult to fabricate, and reasonable in cost. Yet they must be capable of adequate strength at their operating temperature. Table 5 shows the primary materials used. The Time-at-Load is used to establish allowable stress using data in the ASME Codes [25].

|

|

For engines where fuel consumption issues override initial cost, such as large trucks and locomotives, more expensive materials with higher temperature capability could be used. However, the example truck engine shown above uses the materials in Table 5. Therefore, there is room for some efficiency improvement.

Previous Chapter | Next Chapter